Multiplayer and maximum absorption

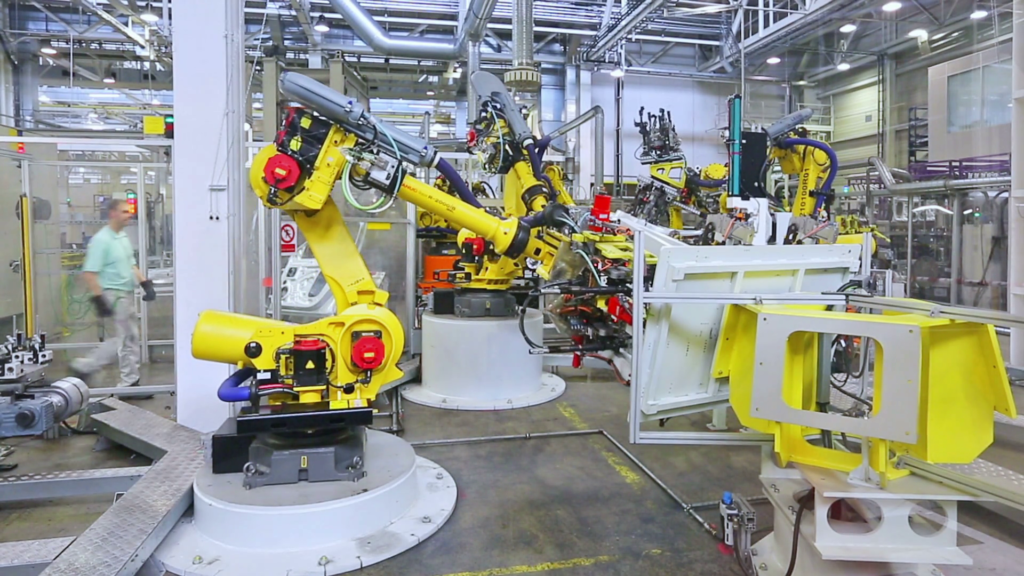

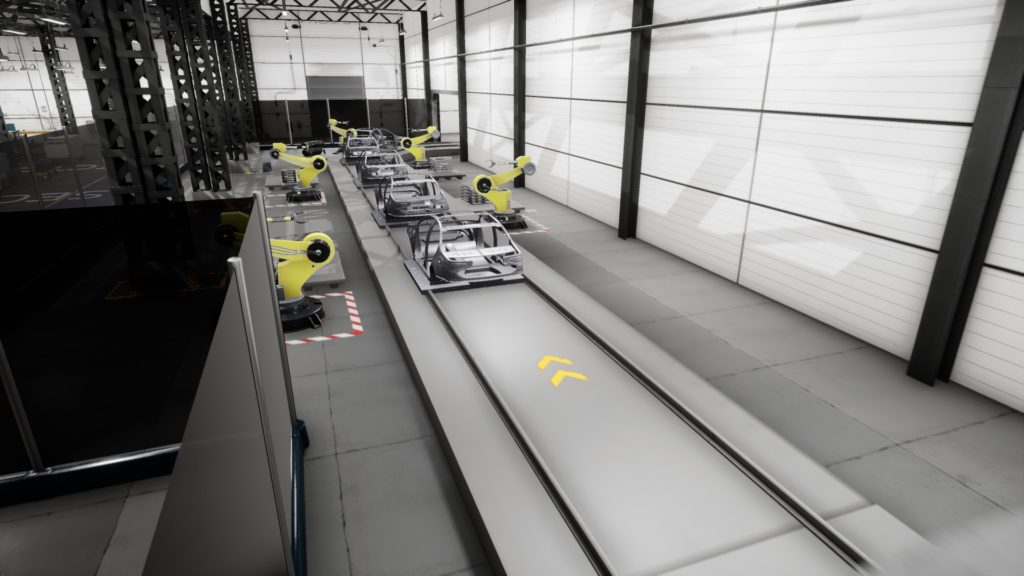

With some of the recent updates we have added even more content to showcase how VR can be used to train workers of the automotive industry by adjusting new interactions with different car details and the process of their creation. It is all about focusing on the training process that requires skills and patience. To say the least, we have made the simulator accessible for multiple users at the same time. Now, there is a custom solution that helps workers train together with a visible chart that displays their results. Automotive plants have a vast number of workers that need to be properly trained. We offer a platform that is a cost-effective and innovative solution for employee training.